What are SIPS?

Structural Insulated Panels – SIPS – are an advanced method of construction, offering superior insulation, structural strength and air-tightness over traditional construction methods or systems. SIP panels are used in floors, walls and roofs for residential, industrial, educational and commercial applications, providing ecologically friendly and energy efficient buildings.

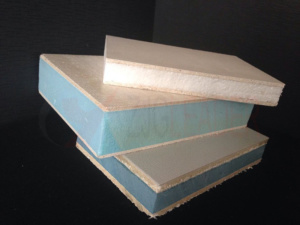

SIP technology has been developed around composite (or sandwich) panel techniques, creating a product with excellent structural and thermal characteristics.

SIPS consist of two parallel faces – usually Oriented Strand Board, sandwiching a rigid core of Polyurethane (PU) foam or Expanded Polystyrene (EPS or XPS), making them lightweight, quick to erect and free from problems of compression shrinkage and cold bridging associated with other forms of construction.

Facings materials vary with the advanced techniques, MgO board, fiber cement board, wood bonded cement board, etc. These boards currently have replaced traditional facing, OSB. Our Mgo board is also a perfect choice used as facing boards.

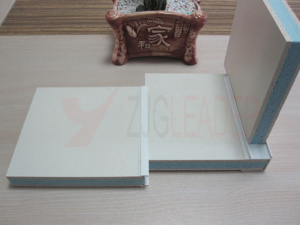

Product size

- Thickness:20mm,40mm,50mm,75mm,100mm,150mm etc.

- Max width:1200mm

- Length:can customize dimensions as request by customers.

Specifications of sip panel:

1.Thermal insulation

2.Lightweight

3.Endurable in use

Our advantages of sip panel:

1) Fireproof grade A1: road to safe life

2)Light weight, High Intensity: Road to a spacious life

3)Soundproof and heat preservation: road to peaceful life

4)Labor efficiency,easy and fast installation: road to economical life

5)Green and safe material: road to an eco-life